Cut Resistant Gloves - The Technology

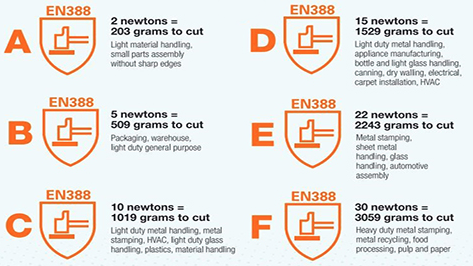

The Xscape cut resistant gloves use a lightweight high strength oriented-strand gel spun through a spinneret. The base material is high performance polyethylene (HPPE).The strength to weight ratio’s for Dymacut5 is up to 15 times higher than steel and about 40% higher than Aramid. Dymacut5 is also 15 times more resistant to abrasion than carbon steel. Our product has the worlds strongest fibres and has a strength to weight ratio rating even than Kevlar. These gloves exceed the old cut level 5 and conform to EN388:2016 Cut Level C

A cut level 3 version of the Dymacut5. The Xscape CL3 cut-resistant gloves use Dymacut3. This material has less HPPE thread and a little more bulking material making it a more cost effective option for customers who don’t require cut level 5. The base material is High Performance Polyethylene(HPPE)

GLOVE COATINGS

BLACK PRECISION DIPPED PU

BLACK PRECISION DIPPED PU

Polyurethane (PU) when precision dipped, makes the thinnest coating available for cut-resistant gloves. PU is, however, not as abrasion resistant as NBR or Latex but offers the highest level of dexterity. This makes PU coatings ideal for small component handling or even where the user may need to regularly write - truly like a second skin. PU coated gloves, coupled with cut level 5 protection, are recommended for production lines, automotive, mechanics, metal handling, warehouse, forklift driving and construction. A more unusual use is for archaeology where full protection is needed, but also dexterity.

BLACK GRISTLE LATEX

BLACK GRISTLE LATEX

Latex Gristle provides excellent grip in the wet. The cut-resistant gloves using this coating are not as dextrous as PU or Nitrile. Instead the wrinkled finish makes the gloves ideal for handling large, bulky or heavy items with ease where high cut-protection is essential. Coupled with a cut level 5 liner latex-coated gloves are recommended for sheet handling, steel handling, refuse and recycling, automotive, construction, maintenance, utilities and civil engineering.

PRECISION DIPPED NBR

PRECISION DIPPED NBR

Precision dipped Nitrile Butadiene Rubber(NBR) is similar to PU. Thanks to the precision dipping process the cut resistant gloves using this material are soft-coat safe. They remain extremely dextrous, only slightly less so than PU, and give excellent abrasion resistance. PD-NBR also has good resistance to oil and chemical splash. PD-NBR coupled with a cut level 5 liner is recommended for sheet material handling - specifically for soft coat, steel handling, steel fabrication, automotive, construction, maintenance, utilities, civil engineering, climbing and roping.