The Cut Resistance Tests

Cut Resistance For The Workforce

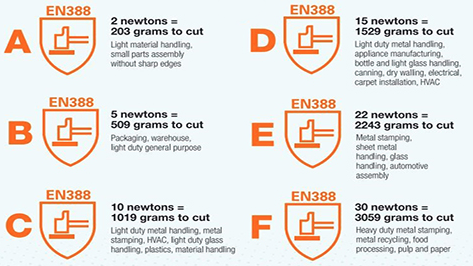

The subject of cut resistance is very complex and has given rise to a standard system of measurement in the UK and Europe known as EN388:2016 .

The EN388 standard evaluates cut resistance by using a circular blade of 40mm diameter. This rotates against the direction of movement with a load of 5 Newtons. The blade traverses back and forth over a small distance of approximately 50mm across the material being tested.

The number of cut cycles before the material fails, or breaks through, is measured and converted into a rating of 1 to 5. The control measure is a cotton fabric against which the cut-resistant material is compared. This is summarised as follows:

0 = 0 to 1.2 cycles prior to failure or breakthrough

1 = Greater than 1.2 to 2.5 cycles

2 = Greater than 2.5 to 5.0 cycles

3 = Greater than 5.0 cycles to 10.0 cycles

4 = Greater than 10.0 cycles to 20.0 cycles

5 = Greater than 20 cycles

In 2016 EN388 was updated to include ISO 13997:1999 which is in line with the North American standard of ANSI/ISEA 105-2016 which also uses a similar system of cut levels A1 -A

Cut resistance is a precise measurement conforming to globally recognised standards. With Flexion garments, you can rely on standards being achieved that exceed standards embodied in EN388:2016 Level C. An example of the ISO13997 cut resistance test which is carried out on the fabric used in the production of garments is shown in the video below. This is carried out by the institute Ricotest, an Italian testing house. ISO13997 is embodied in the standard EN388:2016.

Puncture Resistance

This is another test carried out to EN388. It measures the ability of a material to withstand piercing or intrusion by a foreign object. The testing for this varies with the type of object used, with the principal differences relating to the sharpness and force of an object.

In the case of gloves, EN388 specifies the use of a pencil like object, with a flat tip of 1.0mm. There is a limited correlation in tests of other materials where a low impact very sharp object like a hypodermic needle is used. Therefore tests that measure puncture resistance are application-specific. They vary from examples like packaging through to bullet-proof vests and needle disposal facilities.

Dymacut and Dymatex Cut-Resistant Materials

The sister company of Flexion Global was formed in 1992 manufacturing chainsaw protective clothing. The focus of the manufacturing process has always been to produce the most comfortable, lightweight and fashionable products. These are combined with the highest level of protection possible. This foresaw the introduction of the Dymatex material. This is a lightweight high strength orientated strand gel spun through a spinneret, with a base material of HPPE.

Dymatex has a strength to weight ratio of 15 times higher than steel, with abrasion resistance around 15 times higher than carbon steel.

In 2013 Dymacut5® was born. Using the same technology as used in the Dymatex5® fabric, additional fibres such as Lycra were introduced to produce the lightest, thinnest and most flexible of materials. These are capable of producing a level of cut resistance 6 times higher than that specified in the EN388 Cut Level 5 index. This product was introduced predominantly for the sheet material industries, but also provided protection for a variety of high-risk applications.

Innovation

Flexion Global continues to innovate, and as the manufacturer with its own wholly-owned facility in Portugal is equipped to maintain its position in the forefront of cut resistance. The market for work gloves, Level C protection, cut 5 gloves, cut 3 gloves and safety gloves, in general, continues to evolve as health and safety becomes more and more important in industry.